Hongyue slope protection anti-seepage cement blanket

Short Description:

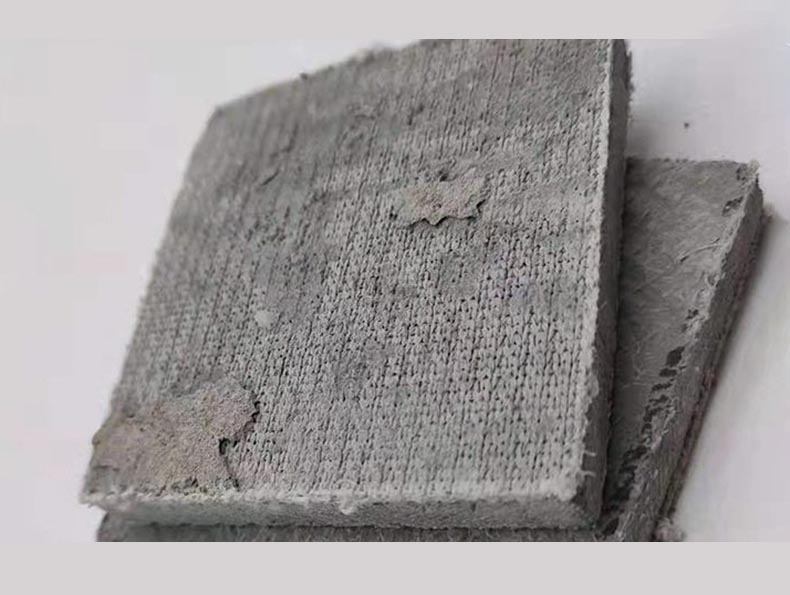

Slope protection cement blanket is a new type of protective material, mainly used in slope, river, bank protection and other projects to prevent soil erosion and slope damage. It is mainly made of cement, woven fabric and polyester fabric and other materials by special processing.

Products Description

Cement blanket is a needle punched composite method of cement waterproof blanket, which is a blanket like material made of two (or three) layers of geotextile wrapped with specialized cement needles. When it comes into contact with water, it will undergo hydration reaction and harden into a very thin waterproof and fire-resistant durable concrete layer. A flexible blanket made of functional composite materials can be formed into a durable concrete like layer with the required shape and hardness by simply watering. By using different formulas, it is possible to form concrete like structures that are resistant to seepage, cracking, heat insulation, erosion, fire, corrosion, and durability. When the bottom of the product is covered with a waterproof lining during construction, there is no need for on-site mixing. It only needs to be laid according to the terrain and technical requirements, evenly mixed with alcohol or soaked in water to make it react. After solidification, the fibers enhance the strength of the composite material blanket.

Performance Characteristics

High mechanical indicators and good creep performance; Strong corrosion resistance, excellent aging and heat resistance, and excellent hydraulic performance.

Scope of Application

Ecological ditches, rain-shower ditches, mountain ditches, highwaydrains, temporary diversion ditches, sewage ditches and so on.

Specification for Cement Blanket

| Number | Project | Index |

| 1 | Mass per unit area kg/㎡ | 6-20 |

| 2 | Fineness mm | 1.02 |

| 3 | ultimate tensile strength N/100mm | 800 |

| 4 | Elongation at maximum load% | 10 |

| 5 | Resistant to hydrostatic pressure | 0.4Mpa,1h no-leakage |

| 6 | Freezing time | Initial setting for 220 minutes |

| 7 | Final set for 291 minutes | |

| 8 | Nonwovens-woven fabric peel strength N/10cm | 40 |

| 9 | Vertical permeability coefficient Cm/s | <5*10-9 |

| 10 | Resistant to stress (3 days) MPa | 17.9 |

| 11 | Stability |